New Report: The Promise of Turquoise Hydrogen

The energy sector may be on the precipice of metamorphosis. On October 1st, Hydrogen Europe (HE) released a new report announcing the promising applications for turquoise hydrogen made from pyrolysis.

Currently, the vast majority (95%) of global hydrogen production is derived from fossil fuels using various thermochemical processes. The report contends that turquoise hydrogen produced via pyrolysis, also known as methane splitting or cracking, is a climate-friendly hydrogen production process that could transform the energy sector, enabling a clean pathway to low-carbon hydrogen production at scale.

In this article, we’ll review the report’s summary, break down the pyrolysis process, and discuss what it could mean for the world.

The Hydrogen Europe Report Summary

The piece entitled Pyrolysis: Potential And Possible Applications of A Climate-Friendly Hydrogen Production was a collaboration between HE and the German Technical and Scientific Association for Gas and Water (DVGW). It was published in concurrence with the EU’s “Hydrogen Week.”

Hydrogen is the fuel of the future—a powerful element that can be used to generate electric power in fuel cells, heat buildings, and make synthetic vehicle fuel. But to produce usable hydrogen, it must first be separated from its constituted organic compounds.

Traditionally this uncoupling was an energy-intensive process. Autothermal reforming (ATR), steam methane reforming (AMR), and partial oxidation have been the usual thermochemical hydrogen production processes. But these conventional processes weren’t “clean.” They produced approximately 10kg of CO₂ emissions per kg of hydrogen.

The energy industry uses the colors of hydrogen to differentiate between them easily. For example, in traditional natural gas-into-hydrogen extraction methods that don’t capture carbon emissions, the resulting matter is called gray hydrogen.

To combat this problem, European policymakers have encouraged “blue” production methods that combine traditional fossil-fuel carbon synthesis with carbon capture technology that filters out the CO₂ before it can reach the atmosphere. And in recent years, turquoise hydrogen production has emerged as a potential solution—an efficient, clean, and low-carbon (if not carbon-negative) alternative.

What Is Methane Pyrolysis?

The word pyrolysis amalgamates the Greek words for fire (pyr) and solution (lysis) to describe the thermochemical decomposition of organic compounds without oxygen. No oxygen means no combustion.

So, how does methane pyrolysis work?

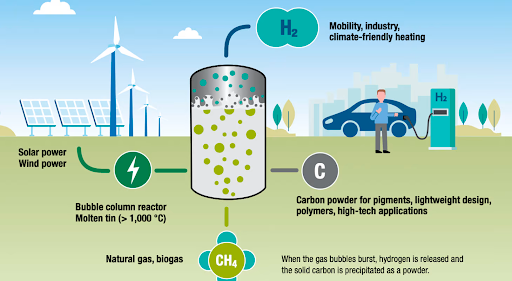

Using a high-temperature reactor, methane (CH4), the primary component of natural gas, is split into solid carbon (C) and hydrogen (H2). This split methane results in clean hydrogen and solid carbon that can be used for various industrial applications. And most importantly, it produces zero greenhouse gas emissions.

Furthermore, the downstream biogas or biomethane used for the process can also be captured to give the process an unheard-of negative carbon balance. The report provided this helpful infographic to show how the process works:

Industry Advantages of Turquoise Hydrogen Production

The development of turquoise hydrogen technology has considerable potential for the future. The possible benefits of producing turquoise hydrogen include:

- A multi-powered process – Although the early applications have primarily focused on a gas-powered process, the pyrolysis reaction can also be powered by renewable electricity via hydrolysis, resulting in zero-carbon hydrogen.

- Less renewable energy needed – According to the report, “Producing 1 kg of zero-carbon hydrogen will in all likelihood require far less energy when produced via pyrolysis than through electrolysis, because the chemical reaction used for pyrolysis requires the equivalent of 13% to 26% of the energy needed by the reaction used.” As a result, countries wouldn’t need to build as much renewable energy infrastructure.

- Installed at point of use – This novel technology can be installed wherever methane resides. It is designed to integrate with standard gas and hydrogen application equipment, which reduces the need to make hefty CapEx infrastructure expenditures.

- Minimal electricity consumption – The fact that the process uses precious little electricity already makes it a superior alternative to blue hydrogen and green hydrogen processes.

- A solid carbon byproduct – Solid carbon has multiple applications in the circular economy, and it can be used in various sectors and improve soil quality.

- Scalability – Turquoise hydrogen is suitable for small, medium, and large applications. The ability to leverage existing gas infrastructure is desirable for smaller producers.

FASTECH: Providing Renewable Energy Solutions

Hydrogen represents the fuel of the future. And turquoise hydrogen could accelerate the green transition as an emissions-free solution. Researchers are excited about the promising nature of turquoise hydrogen, primarily due to its low electricity use, scalability, and carbon as a solid byproduct.

FASTECH is a leading provider of hydrogen fueling infrastructure solutions. Our team offers complete end-to-end services in the hydrogen fuel marketplace. To that end, we have built more than 30 hydrogen stations for leading corporations and energy providers to date.

Contact us today to start discussing your hydrogen project.